The Pontis circle of bridging design and manufacturing

DESIGN FOR RESULTSToday’s society demands products that are faster, more energy efficient, more reliable, more resistant, more accurate or simply better looking. In addition to the functional performance, sustainability is a driving force for innovation. The answer lies in advanced composites: with new applications for existing materials and new, improved varieties.

Pontis offers customized solutions on both counts. We translate your (product) ideas into optimized composite solutions. Whether this is a new idea, the translation of an existing product into a composite solution or improving an existing composite product: we are your skilled and involved partner to guide you through the world of composites.

From the aerodynamic shell of the world’s fastest bike to the largest rotor blade in the world, from a lightweight pedestrian bridge to rooftop wind energy systems: our experts will work with you to create designs fit for manufacturing, resulting in successful composite products that meet all your requirements.

Design for manufacturability With 25 years of experience in developing composites for industries ranging from construction to aerospace, our specialist design team is fully equipped to meet whatever needs your company may have. At all times we keep a key focus on manufacturability, resulting in a cost effective and efficient design process. Thanks to our global work for A-list clients we constantly remain at the forefront of new developments and we can leverage on a strong international network of suppliers and external resources.

|

|

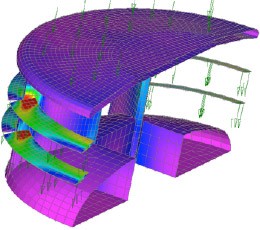

Structural DesignAn intelligent structural design is fundamental to any successful composite product in terms of cost-of-energy, ease of manufacturing, time to market and product quality. Our specialised structural design group offers a wide range of services from conceptual design to fully tested and certified products.

We use market-leading design packages (such as CATIA, FEMAP, Nastran, ..) alongside internally developed design and optimisation tools, which seamlessly interface with all common file formats that you may use.

Recent projects

EvaluationWe are your fully independent expert in design evaluation, always with the objective of finding the best solution to meet your requirements. We assess composite designs on strength, practicality and overall efficiency including material selection and cost. We offer unbiased advice and will, if necessary, mediate in complex discussions with third parties. Our significant practical experience in the field allows to eliminate many common issues.

Types of evaluation include:

|

|

Recent projects

Redesign: meeting tomorrows standardsThe world of technology is dynamic and continuously challenges us to improve performance and to face new realities. Our design team is specialised in re-optimising existing products to make them fit for tomorrow’s standards, requirements, materials and processing methods. We consider and integrate all relevant aspects (cost, weight, quality and cycle time) in order to provide you with an optimized composite design, excelling in innovative power, cost effectiveness and quality.

Design for manufacturability

Recent projects

|