Pontis introduces turnkey “pre-form” moulding solution

Prefabricated laminate packages reduce in-mould cycle time

Pontis Engineering, specialist in the development of advanced composites, presents its latest innovation in moulding & tooling solutions at the world’s most important wind energy trade show: HUSUM WindEnergy 2012. Through a unique process called “pre-forming” rotor blade manufacturers are enabled to reduce in-mould cycle times and increase output significantly.

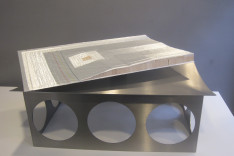

The solution is as simple as effective: availability of the main mould is increased by largely moving the rotor blade production process to sub-moulds. Stacked layers of glass are applied on separate tools. These so called “pre-forms” come in handy modules which can easily be loaded into the main mould. Then the individual modules are smoothly joined, resulting in a rotor blade of the highest quality and durability.

Pontis Engineering director Dirk Jan Kootstra says: “We are proud to introduce this full turnkey pre-form solution including all necessary advice, training and hardware to our international wind energy clientele and we are confident that this innovative approach will set a new standard for rotor blade manufacturing”.

More information:

Dirk Jan Kootstra

DIRECTOR

+31 651 213 023

djk@pontis-engineering.com

DOWNLOAD PUBLICATION